Technological leap demonstrated in successful trial with z.truded bipolar plates at ZBT

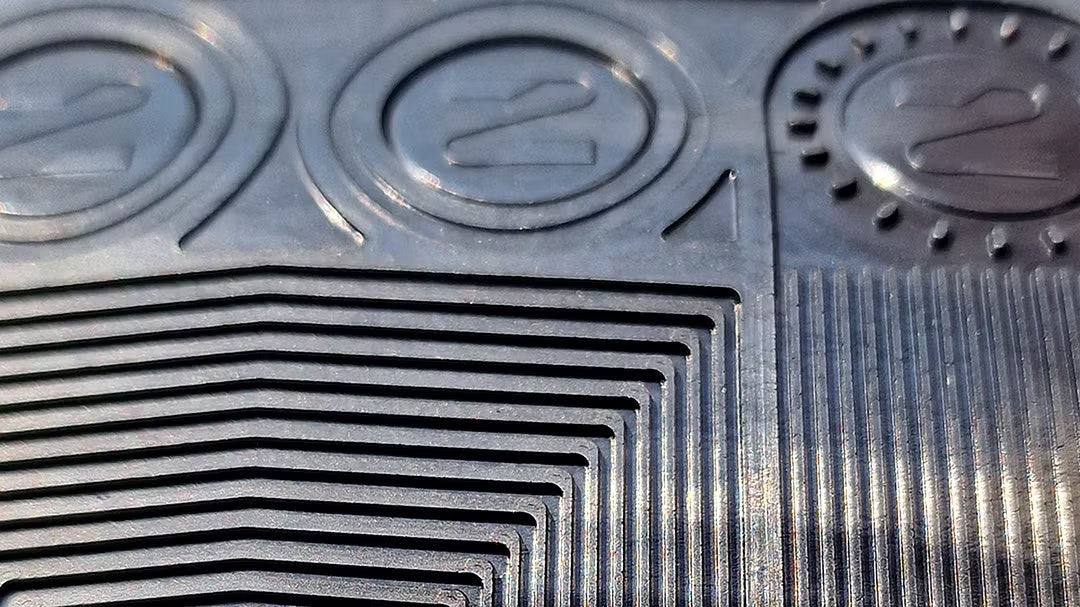

Reliefed has produced z.truded bipolar fuel cell plates with successful results at ZBT – The Hydrogen and Fuel Cell Center, demonstrating the efficiency of the z.trusion technology.

ZBT is Reliefed’s R&D partner for recyclable compound solutions for flow plates, specifically focusing on bipolar plates in this case. The collaboration has been highly productive, with strong commitment from both parties. This has led to significant progress in the manufacturing of next-generation plates with complex designs, all enabled by the z.trusion technology, which unlocks design freedom, efficiency, and scalability in one single step.

The trial was arranged to provide ZBT with exclusive insight into the z.trusion technology and to showcase the simplicity of setting up production. The z.trusion tool is easily assembled on existing extrusion lines as a retrofit, which shortens the path to production. In a single day, the tool from Reliefed was installed, commissioning was prepared, hundreds of plates were produced, and the tool was dismantled, altogether validating the effectiveness of the technology.

For optimal function and endurance, the material compound is key. In the trial a 73% graphite compound, identical to that in the z.trusion tech centre, was used to make recyclable plates with high structural precision to a production speed of 20 seconds per plate, exceeding set goals in this trial.

"I am super excited about the results we have achieved using z.trusion for fuel cell plate production.”, says Marcus Berggren, CTO for Reliefed. “The tests conducted together with ZBT is a real statement of the possibilities z.trusion brings to the hydrogen arena. Thank you, Marco and Paul, for a great collaboration. I look forward to the continuation."

Dr. Marco Grundler, Group Leader Compound Technology at ZBT, adds:"Many thanks for the excellent cooperation, which made it possible to successfully launch the continuous production process extremely quickly with an optimised compound material."