The industry is ready for a shift

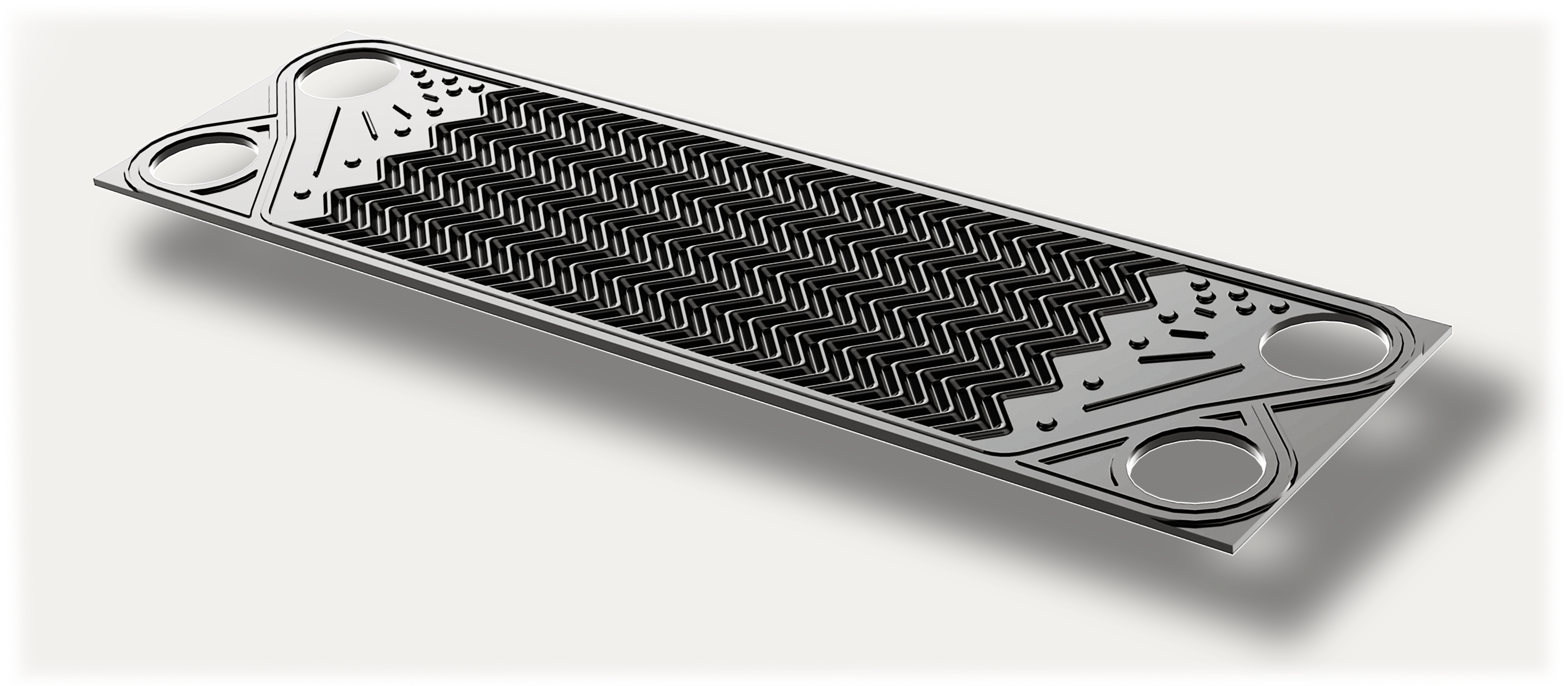

Non-metallic materials, such as polymers, composites, technical ceramics, etc., offer key advantages over metal flow plates:

- Lightweight

- Corrosion-resistant

- Greater design flexibility

But despite their potential, non-metallic flow plates have yet to gain widespread adoption as a viable alternative to metal flow plates in heat exchangers, fuel cells, cooling systems, etc. The primary obstacle is cost – conventional manufacturing processes make non-metallic flow plates prohibitively expensive to produce at scale, reinforcing metal as the dominant material choice.

We make non-metallic flow plates competitive

At Reliefed, we have invented a new way to manufacture non-metallic flow plates of any kind, delivering scalable, cost-effective and high-performance plates.

Our flow plates are used in various applications:

- Heat exchangers

- Fuel cells

- Flow batteries

- Electrolysers

- Cold plates

- Direct air capture systems

Giving you a competitive edge

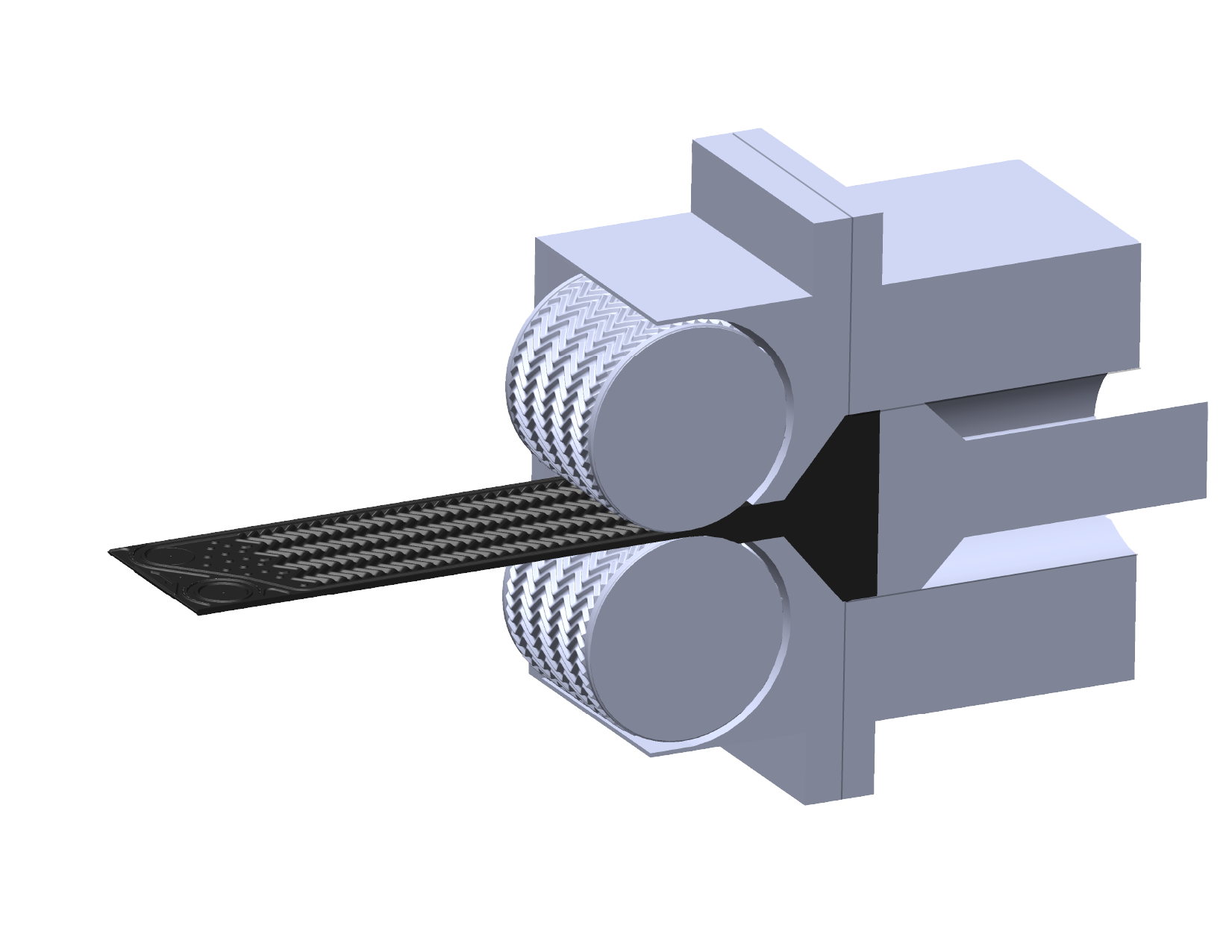

A technology born to create flow plates

Reliefed's patented manufacturing technology, z.trusion, is mastering high-speed, continuous mass production of flow plates while bringing design freedom and precision in the details.

The value provided:

- One-step inline production

- Unseen production rate

- Superior cost efficiency

- Non-metallic plate (no corrosion issues)

- Material agnostic (graphite composites, SiC, AlN, polymers, etc.)

- Increased design freedom (asymmetric design)

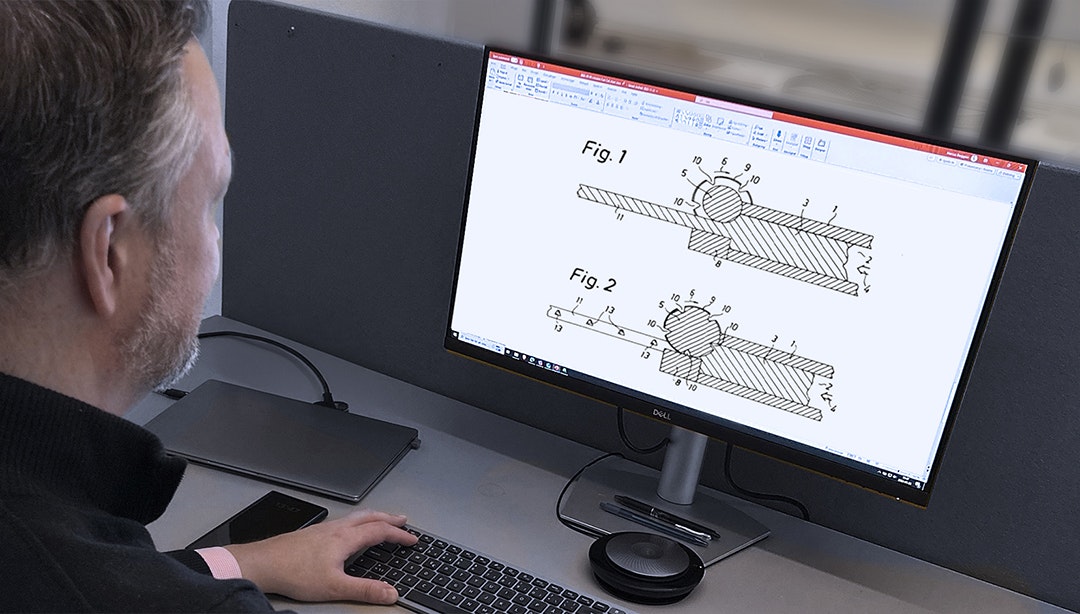

Global innovation, patented worldwide

The z.trusion technology and flow plates solutions are invented by Reliefed and protected worldwide by an extensive and growing patent portfolio.

- 14 patent families

- 46 granted patents

- 34 patents pending

- Worldwide coverage